Imagine a SCADA system that you can setup from start to finish without buying a single piece of software or fighting with license keys and proprietary WINDOWS only software, and that doesn’t depend on any external cloud resources but can still be setup and configured right from your local web browser.

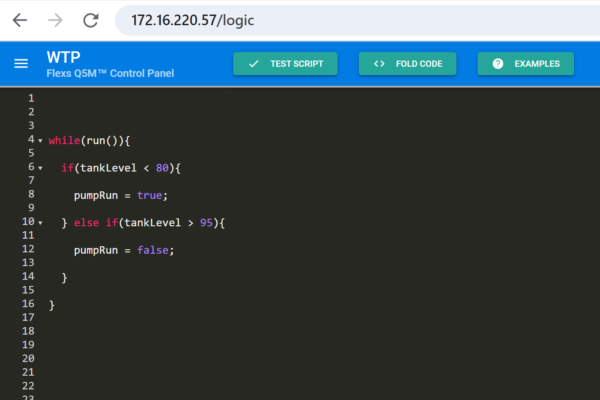

All of our Flexs series programmable logic controllers are programmable in a language similar to structured text but more powerful and easier to use.

The syntax is the same as JavaScript with the addition of variable bindings that allow you to seamlessly work with input and output channels as if they were local variables.

For a brief overview on why we think this is a better option than legacy ladder logic see our article here

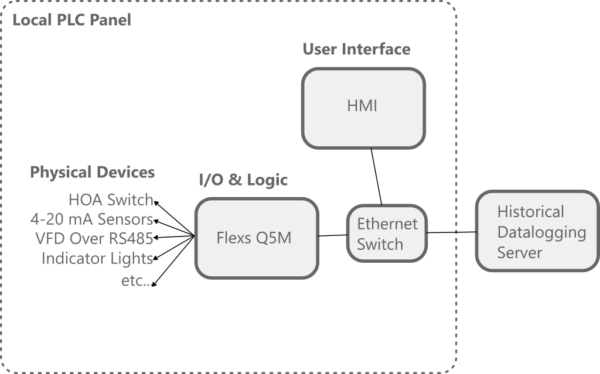

How the Flexs Q5M would work in a typical SCADA system

- The Flexs Q5M would directly interface with sensors and actuators while also running the logic to make the entire system function.

- The HMI would provide real-time monitoring, alarm management, setpoint control and user authentication.

- Historical Datalogging; While our devices support standard ModBUS TCP and can be polled and logged by any off the shelf HMI or datalogger. ModBUS TCP does not offer any built in security features and also lacks the ability to store and push (i.e. continue logging when communication is down and upload once comms are restored) so we’ve created a easy to deploy, self contained software application that allows you to instantly setup your own cloud portal. Once that is complete you can log in to the local cloud portal and add your devices. Once devices are added it will automatically start collecting all of the measurements on each channel of your device ready for you to start creating dashboards. Any configuration changes you make on a device are also automatically preserved.

Available as a self contained docker package, compatible with most linux distributions, uses Grafana for visualization and InfluxDB for timeseries data storage.

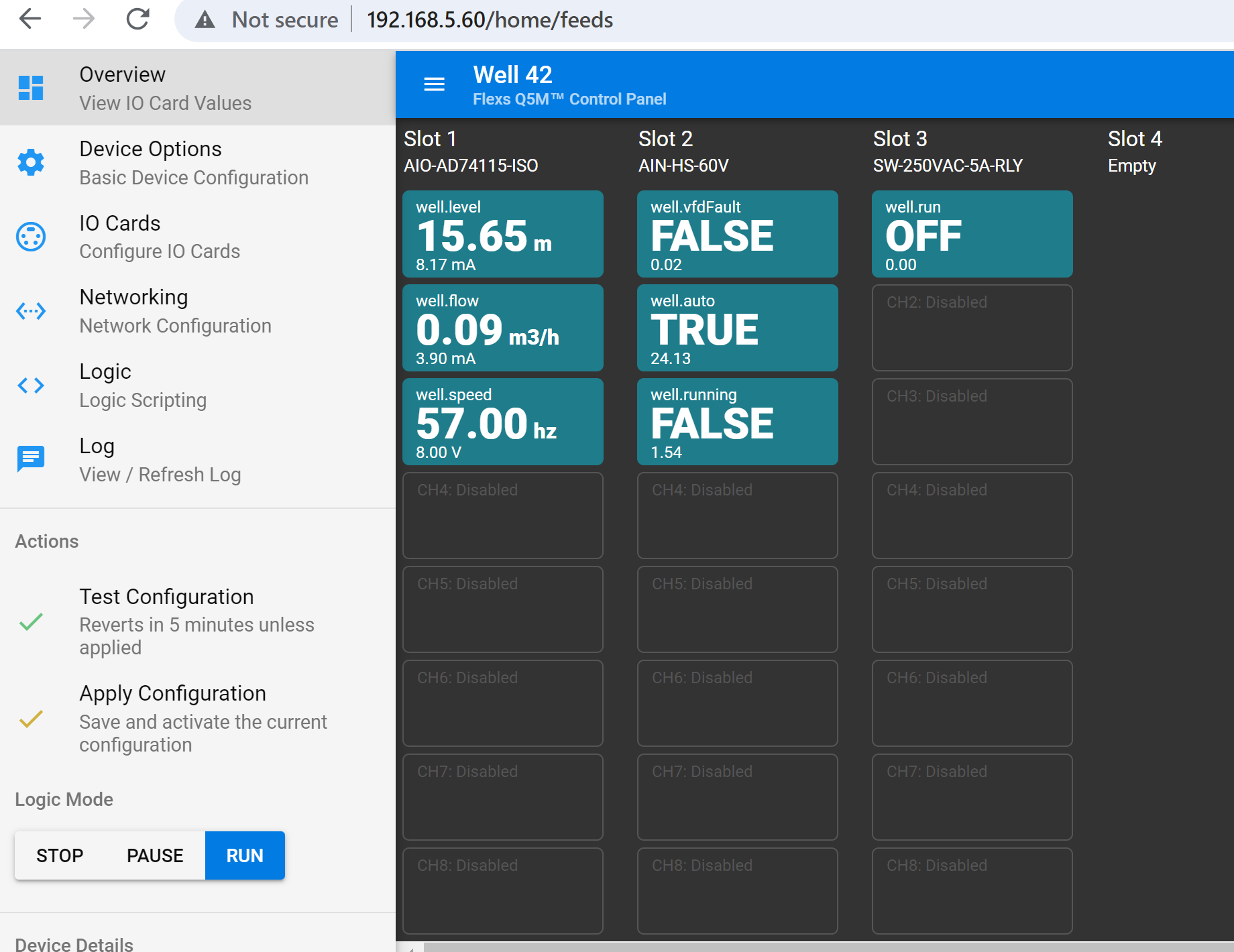

Below we’ll walk through what it would look like to setup a Flexs Q5M to monitor and control a well pump.

First we’ll install our IO cards, for our job today we need to talk to a few sensors and control a pump through a VFD

- 4-20mA

- Well Level (Input)

- Output Flow (Input)

- Drive Speed (Output)

- Discrete Output

- VFD Run

- Discrete Input

- VFD Running

- VFD Fault

- HOA In Auto

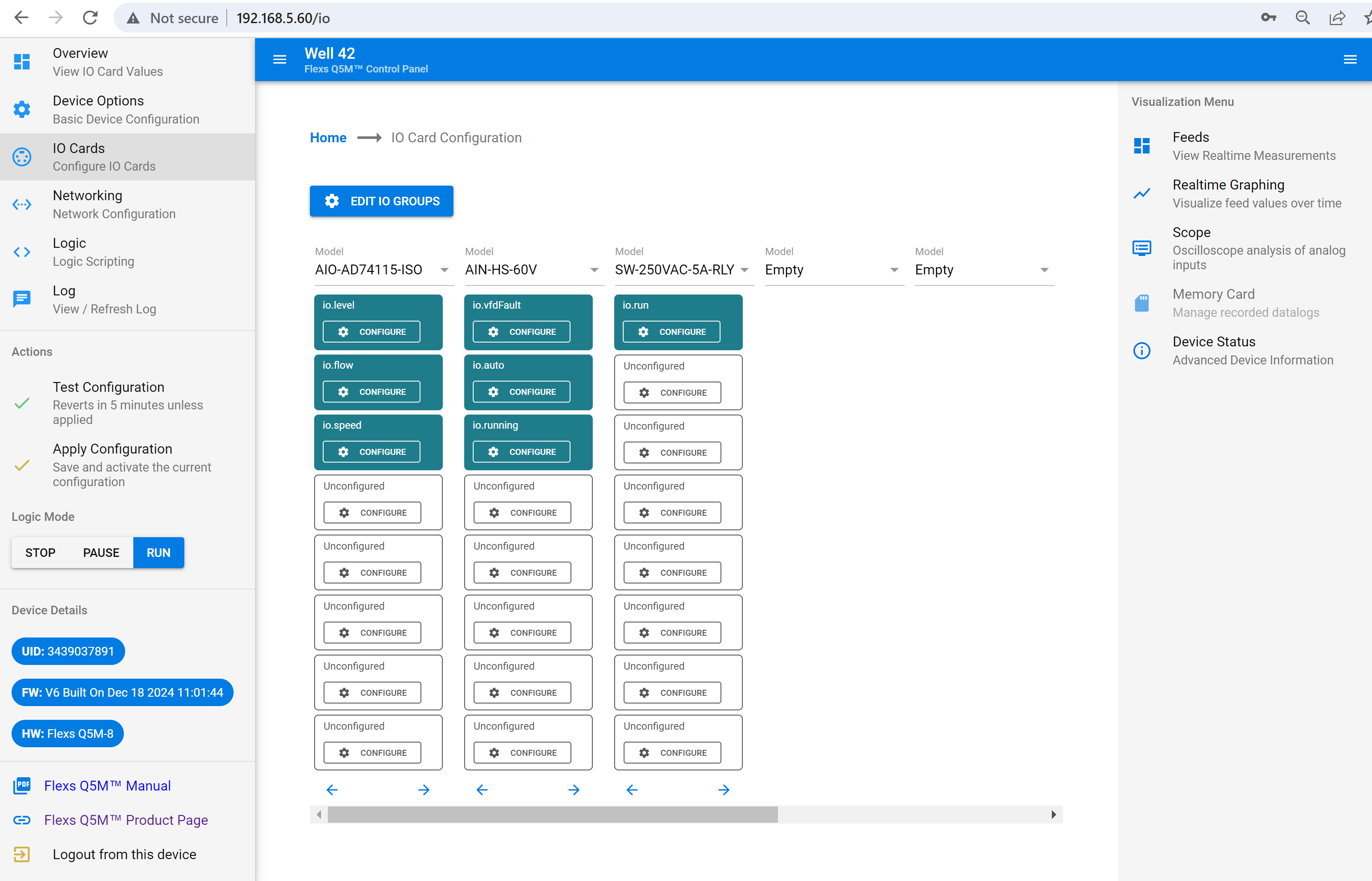

After installing our IO cards let’s powerup the unit and configure our channels.

The PLC is powered from a DC power source between 9-30V so your 12V batteries are in, or standard your 24V power supply.

After powering up your unit, connect your laptop to the Flexs Q5M with a network cable and point your web browser to the devices onboard webserver.

Configuration

Navigate to the IO Cards page from the left sidebar menu and select the card model for each slot.

Now lets give each channel a name and select the type of IO which will be used.

Take note in the second picture below just how many input modes our universal cards support! Gone are the days of having to have a special card for 4-20ma inputs, and another for outputs, and another for thermocouples.

Our card does it all! And includes 4500W of built in surge protection along with 6KV of galvanic isolation!

Ready to connect to your sensors, For loop powered 4-20mA sensors the channels can output a constant isolated 24V regardless of the voltage being used to power the PLC so your sensor readings are always stable, built in diagnostics are also available for short circuit, open circuit etc.