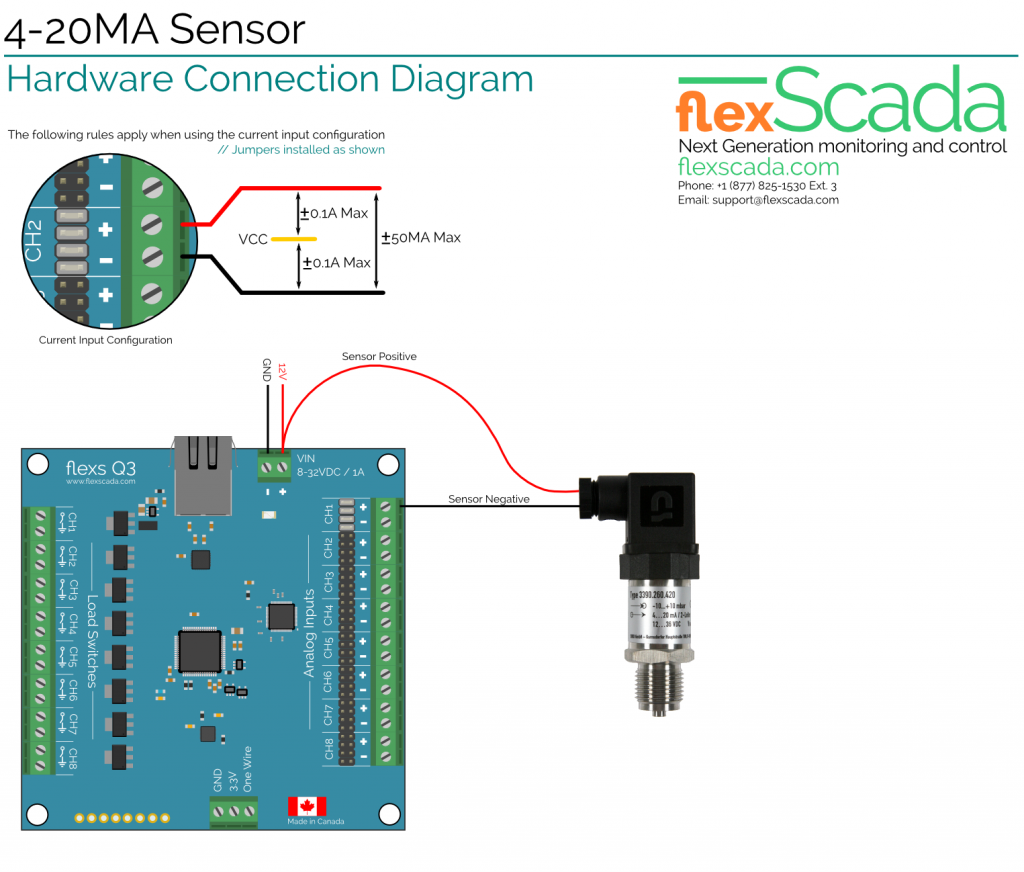

Interfacing to 4-20MA analog sensors with the Flexs Q3 Smart PLC

Sensors or other devices with a 4-20 mA current loop output are extremely common in industrial measurement and control applications. They are easy to deploy, have wide power supply requirements, generate a low noise output, and can be transmitted without loss over great distances. We encounter them all the time in both process control and basic measurement data logger and data acquisition applications.

The idea behind 4-20 mA current loop operation is that the sensor draws current from its power source in direct proportion to the mechanical property it measures. Take the example of a 100 psi sensor with a current loop output. With 0 psi applied, the sensor draws 4 mA from its power source. With 100 psi applied the sensor draws 20 mA. At 50 psi the sensor draws 12 mA and so on. The relationship of mechanical property measurement to current output is almost always linear, allowing the resulting current loop data to be read accurately.

Using the Flexs Q3 configuration assistant, new sensors can be calibrated by either entering the full sensor range or telling the software what the current reading should be.

Nerd Specs:

- Channels: Eight (Simultaneous Sampling)

- Sampling Speed:1KSPS to 16KSPS

- Shunt: 24 Ohms

- Analog Conversion: 24Bit

- Frontend Type: Ultra Low Noise, Non-Isolated Fully Differential