Description

Applications

• Oil Gas Telemetry

• Generator Gas Leakage (Propane/LPG, Gasoline, Etc)

• Battery Hydrogen Buildup

• Fuel Cell Exhaust Monitoring

Overview

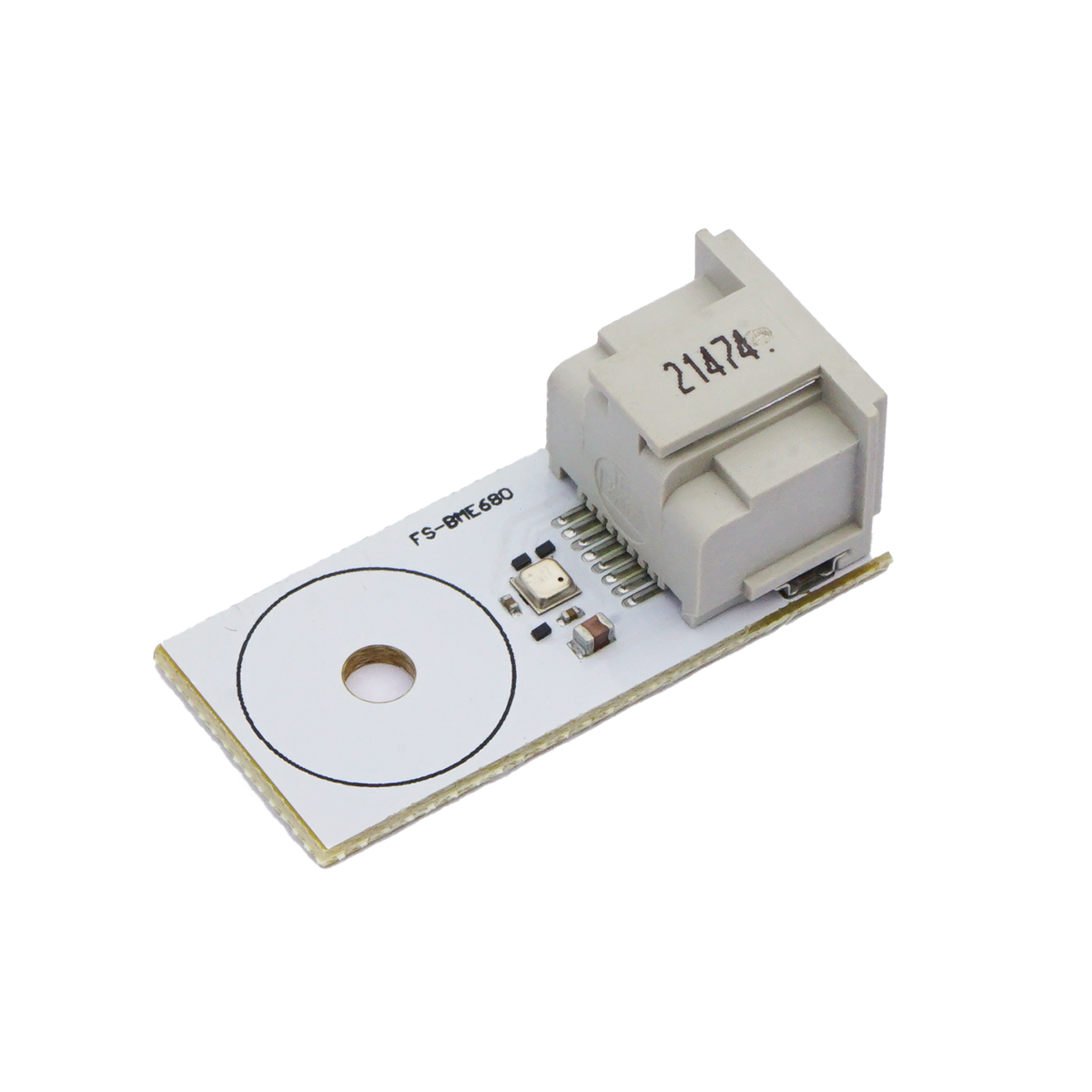

The FS-BME680 is a digital environmental

sensor based on the Bosch BME680 Sensor

The BME680 delivers outstanding environmental measurement performance enabled by

internal compensation algorithms and precise factory calibration of its gas, pressure,

temperature and humidity sensors. The gas sensor can detect Volatile Organic Compounds (VOCs)

and other gases such as carbon monoxide and hydrogen, in the part per billion (ppb) range..

The most common use is detection of combustible gases that may pose a

safety threat to operators or equipment.

Detected compounds include

• Hydrogen (No smell, produced during charging and discharging of various battery types

and is highly and rapidly combustible)

• NG/LPG (Fuel commonly used to power remote sites and is highly combustible )

• Carbon Monoxide (Byproduct of improper combustion of many fuels including

Propane, NG, Diesel and Gasoline, highly toxic, combustible and odourless)

• Benzene (commonly found in cigarettes, paint, and gasoline and is classified as a

human carcinogen by the CDC)

• Formaldehyde (found in many glues, resins, foams, plywood, and cigarettes.

It has been linked to brain cancer, leukemia and is one of the top 10 allergens)

• Styrene (Sweet smelling neurotoxin and carcinogen found in many plastics,

with high concentration levels in styrofoam)

Accuracy

Humidity: ±3%RH (0 – 100%RH)

Temperature: ±0.5°C (-40 – 85°C)

Pressure: 0.12 Pa (equiv. to 1.7 cm) (300 – 1100 hPa)

Response Time: 3s Typ

Combustible Gas: Almost all combustible gasses will be

detected at levels far before the lower flammable limit or

upper explosive limit (LFL or UEL).

Most compounds are detected in the parts per billion (ppb)

although some drop into the ppm range.

Installation

The FS-BME680 sensor is only intended as an aid where certified gas sensors are not required by law

and should never be considered as a replacement for certified and regularly calibrated gas meters.

The FS-BME680 sensor is designed for long life and and detection of a wide range of gas compounds

compared to traditional meters that require frequent sensor element replacements and re-calibrations

Installation should always be conducted by a technician that is familiar with the installation

requirements.

For example if a technician wishes to monitor the hydrogen outgassed from a battery bank

the sensor would need to be installed near the ceiling or highest enclosed point in that space

since hydrogen is lighter than air and will accumulate at the highest point.

If the sensor was used to monitor propane or carbon monoxide from a fuel cell

or generator the sensor should be installed at the lowest reasonable point in the enclosed space

since these gases are heavier than air.

Ventilation, airflow and exhaust temperature also play an important factor and should be considered

during installation.

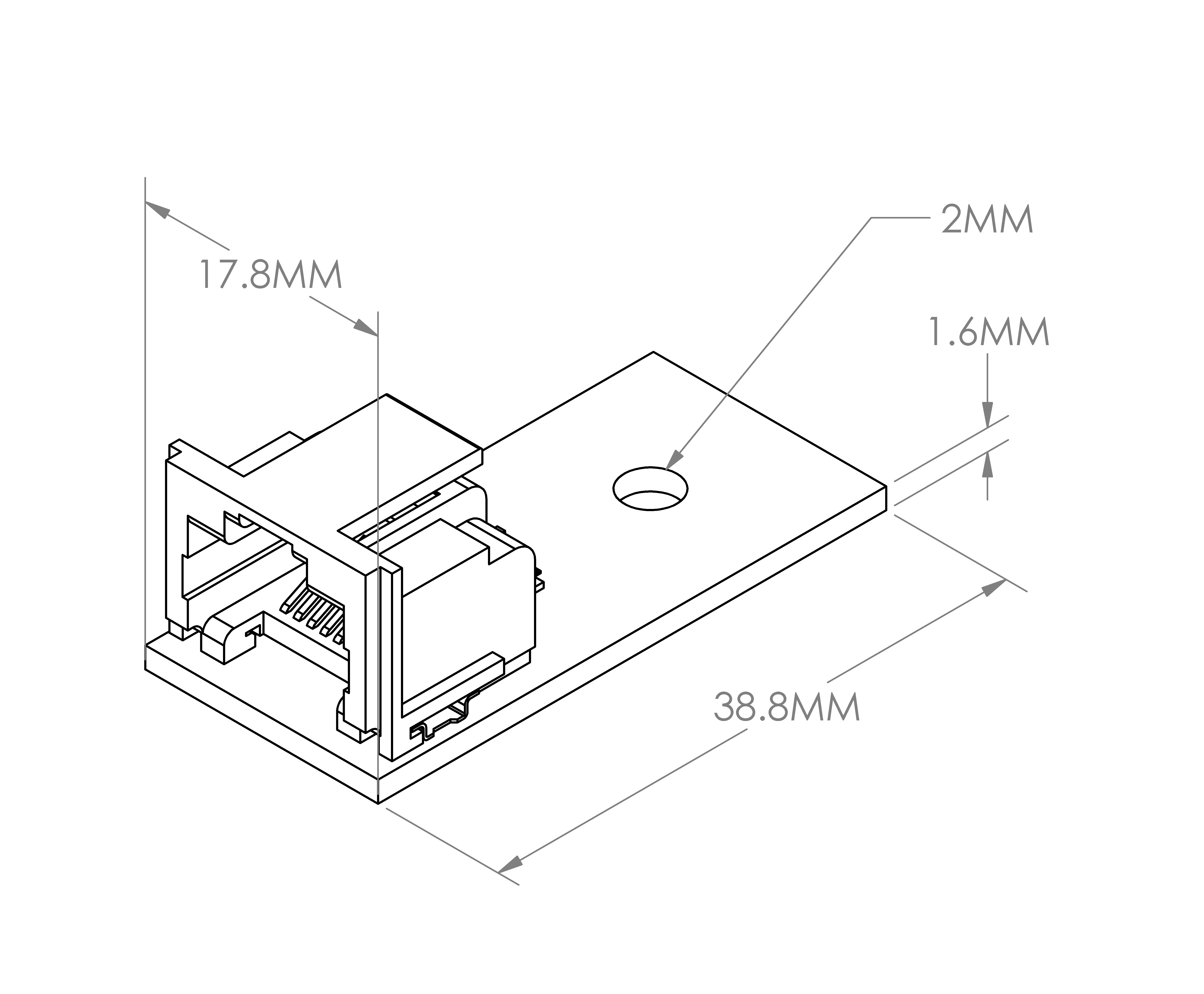

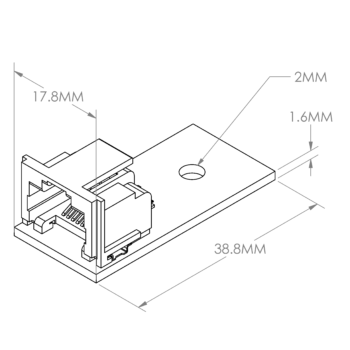

The sensor mounts with a single screw and connects with the Flexs Q5 via a industry standard

non crossover RJ45 (Ethernet) patch cable, and should be installed in a location that is shielded

from physical damage or liquid splashing.

We recommend using shielded RJ45 cabling and limiting the cable distance to less than 10′